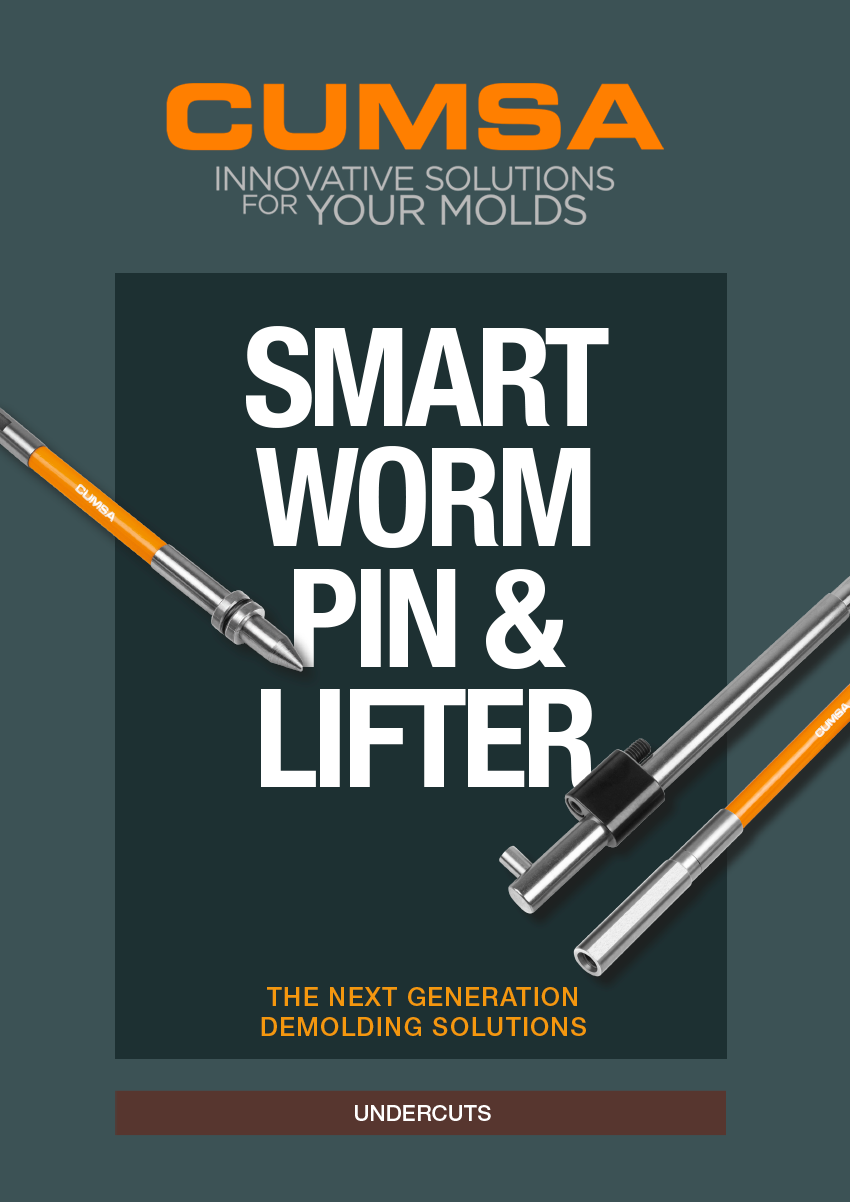

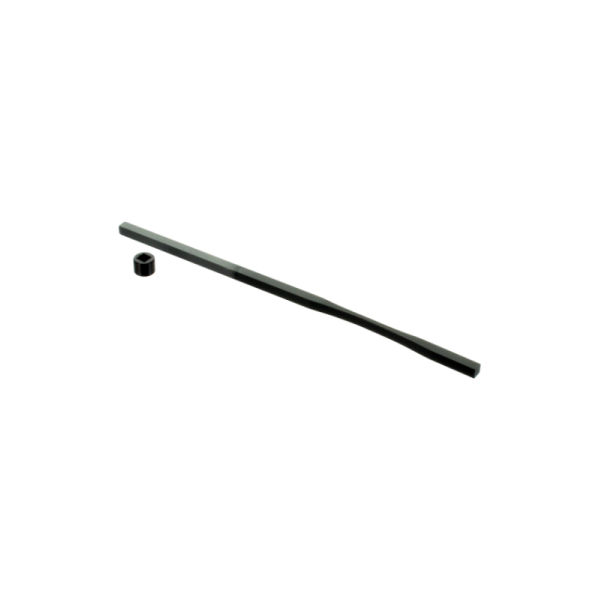

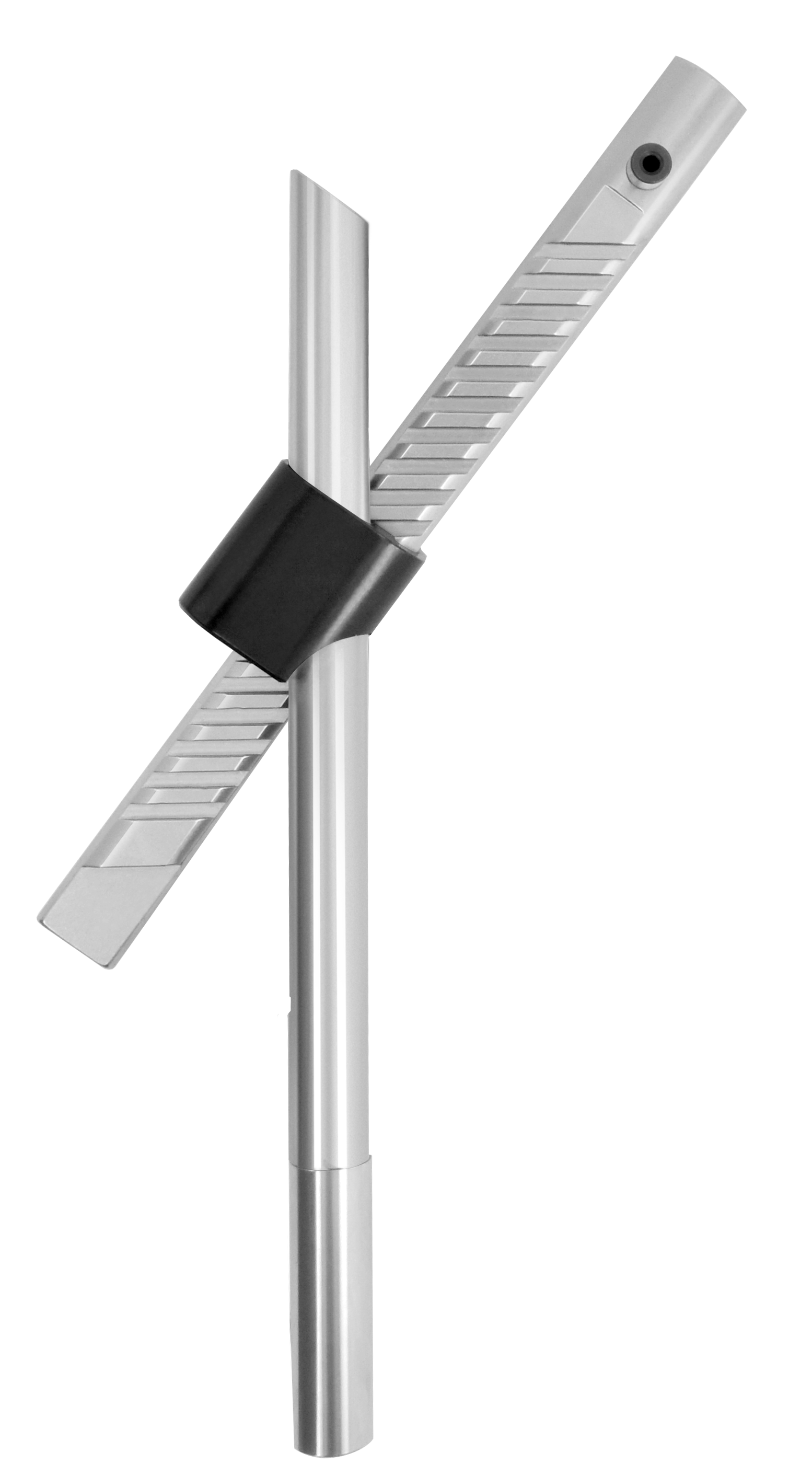

Thanks to its parallel walls, this core allows undercuts to be released in compact areas (only 4mm. thickness).

Include a simple system for adjustment.

A Balinit C® coating ensures smooth movement and reduced wear.

A new feature to this product is that it ejects first then releases the undercut.

Read moreShow less

Include a simple system for adjustment.

A Balinit C® coating ensures smooth movement and reduced wear.

A new feature to this product is that it ejects first then releases the undercut.

What is lifetime of the parts?

Correctly installed sprung cores (following our catalogue installation instructions) can produce more than 1 million parts.

What is the maximum working temperature of the Flexible Cores?

The maximum working temperature is 150°C (302°F).

What properties provide Balinit C?

Balinit C is the best coating to apply to our Sprung Cores. It provides a high superficial hardness and a low friction coefficient, i.e., it protects the part and makes it slide smoothly.

What is the minimum opening dimension?

The opening of the sprung cores is a radial movement. Due to this, at the edge of the stroke, the opening is 2.5mm (0.098”). Here you can see a more detailed technical explanation.

Are there any important application details?

Yes, it is very important to give draft on the undercut, for the PF => 5º.

The radius of 0.10mm, as minimum, has to be kept in the upper surface if it is grinded or machined.

The radius of 0.10mm, as minimum, has to be kept in the upper surface if it is grinded or machined.

Is it normal to see some deviation between the head and the shaft of the PF cores?

Yes, a deviation up to 0,3mm is completely normal as the material is sprung steel and has elastic memory. The part will function correctly as the deviation will settle once the part is installed in its housing.

What is the maximum length we can cut on the shaft?

| Ref. | Max. |

| PF04.... | 40mm. |

| PF05.... | 40mm. |

| PF06.... | 80mm. |

| PF08.... | 80mm. |

| PF10.... | 80mm. |

| PF12.... | 80mm. |

What is the maximum length we can cut on the head?

| Ref. | Max. |

| PF04.... | 12mm. |

| PF05.... | 12mm. |

| PF06.... | 18mm. |

| PF08.... | 18mm. |

| PF10.... | 18mm. |

| PF12.... | 18mm. |

Can these parts be welded?

Welding is not recommended on any of the sprung core products. Welding exposes them to high temperatures which can affect the treated areas, and therefore the characteristics of the spring steel.