Minimum space required for installation, only needs the space of an ejector.

No milling, grinding or hardening other than the machining of detail needed.

Machining for installation is easier due to always being at 90° to parting line.

No need for complex mechanical systems.

Read moreShow less

No milling, grinding or hardening other than the machining of detail needed.

Machining for installation is easier due to always being at 90° to parting line.

No need for complex mechanical systems.

What is lifetime of the parts?

Correctly installed sprung cores (following our catalogue installation instructions) can produce more than 1 million parts.

What is the minimum opening dimension?

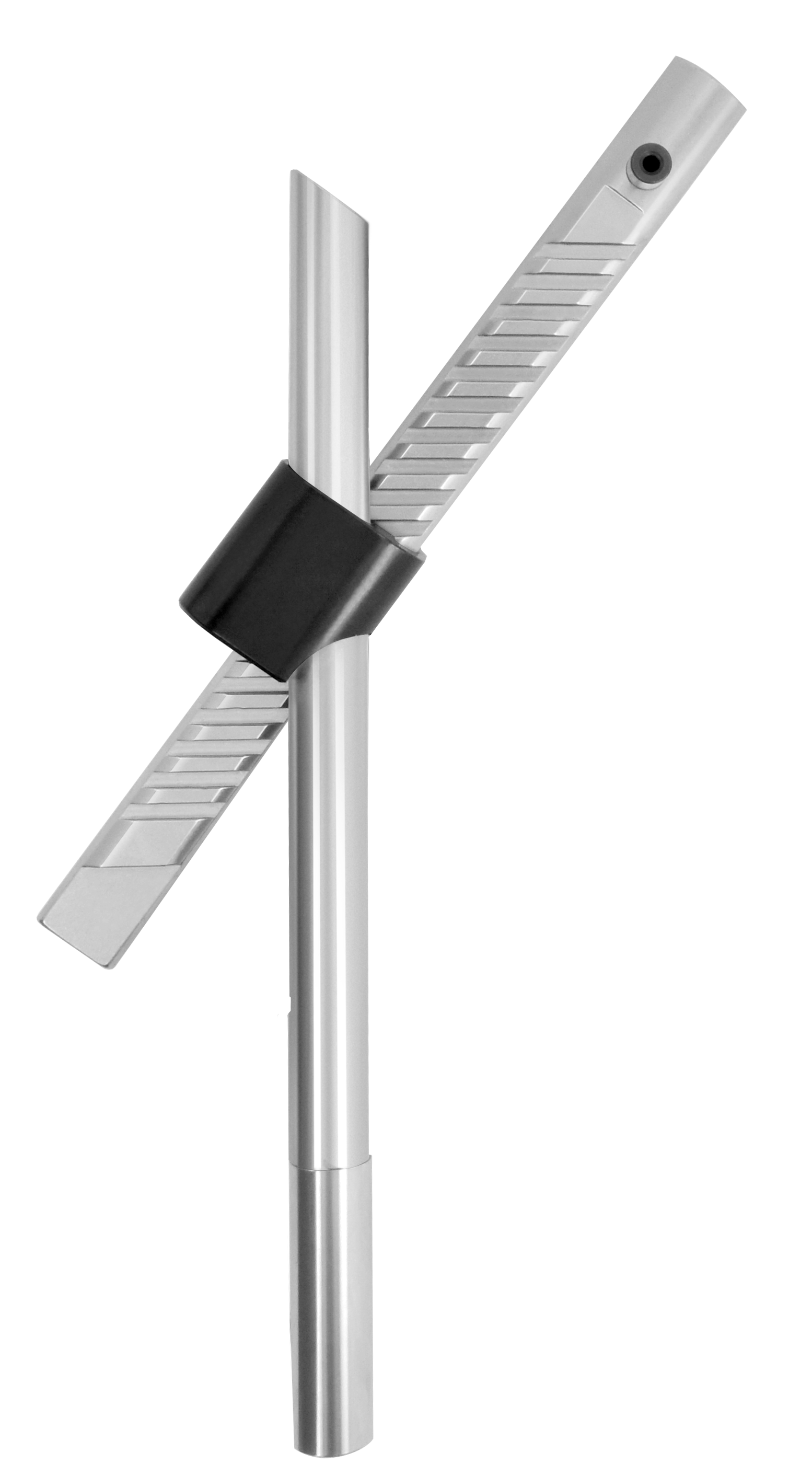

The opening of the sprung cores is a radial movement. Due to this, at the edge of the stroke, the opening is 3.5mm (0.138”), 4.5mm (0.177”) and 5.5mm (0.217”), depending on the model (K dimension in the catalogue). Here you can see a more detailed technical explanation.

Can these parts be welded?

Welding is not recommended on any of the sprung core products. Welding exposes them to high temperatures which can affect the treated areas, and therefore the characteristics of the spring steel.

How do you correctly install a sprung core?

In the catalogue page (view PDF), all the necessary dimensions and tolerances required for assembly are shown, as well as the correct installation procedure.

What is the maximum working temperature of the Sprung Cores?

The maximum working temperature is 150°C (302°F).

Is it necessary to position the sprung cores?

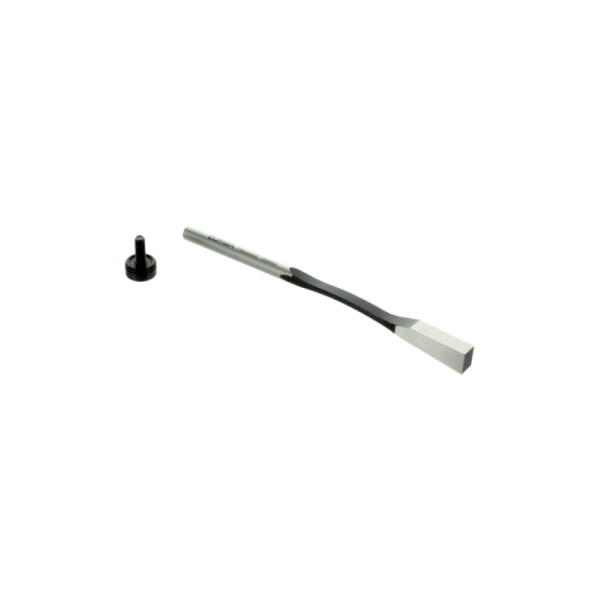

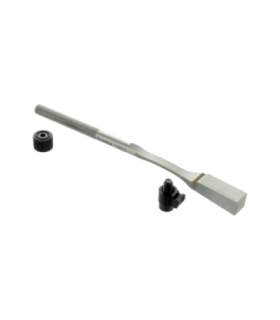

The sprung cores have a flat on the side of the shaft to position them, this must be used to avoid the sprung core turning while fixing it to the ejector plates and therefore preventing it to function in a forced position.

Is it possible to add a surface treatment to the sprung cores head?

We only recommend treatments using Balinit C, as this is the only one that is applied at temperatures below the 150°C / 302°F, therefore preventing changes to the properties of the spring steel. Other treatments like nitriting, TIN, PVD…. are not recommended as they can reduce the sprung core life.

Is it possible to reduce the 6º angle to reduce the dimension D?

Yes, it is possible, but always maintaining at least 3º.

Is it possible to make lateral shut off angles on the dimension B?

Yes, we recommend a minimum of 2º per side.

Can the part be adjusted with the mold cavity?

Yes, because the 6º angle supports the shut off of the head in its location hole.

What is the minimum size required for the shut off area on the 6º face?

It must have a minimum of 5mm plus the part detail in the C dimension of the sprung core.

Are there any important application details?

Yes, it is very important to give draft on the undercut, for the PW => 2º.

The shaft has to be keyed.

The shaft has to be keyed.

What is the maximum length we can cut on the shaft?

| Ref. | Max. |

| PW060622 PW060822 | 10mm. |

| PW060630 PW060830 | 45mm. |

| PW080825 PW081025 PW081225 | 15mm. |

| PW081030 PW081230 PW101430 PW101630 PW101830 | 45mm. |

What is the maximum length we can cut on the head?

| Ref. | Max. |

| PW060622 PW060822 | 10mm. |

| PW060630 PW060830 | 18mm. |

| PW080825 PW081025 PW081225 | 13mm. |

| PW081030 PW081230 PW101430 PW101630 PW101830 | 18mm. |

The ejection stroke can be higher than the C dimension on the catalogue?

Yes, if the sprung core is correctly keyed, therefore when returning to its hole will not suffer any pressure on the spring area.