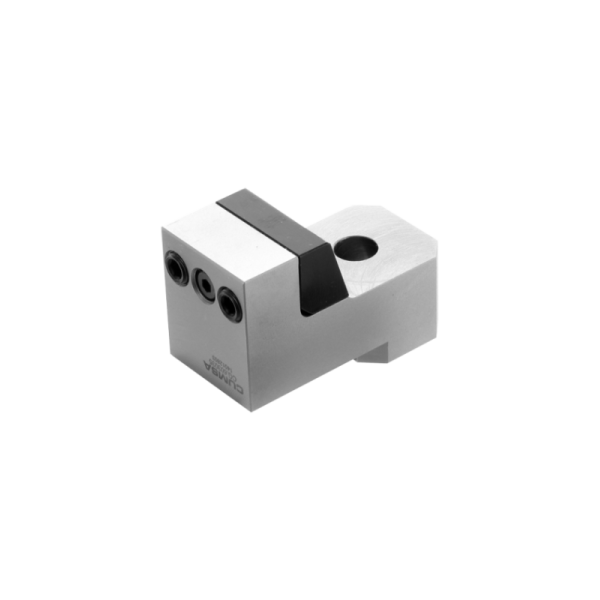

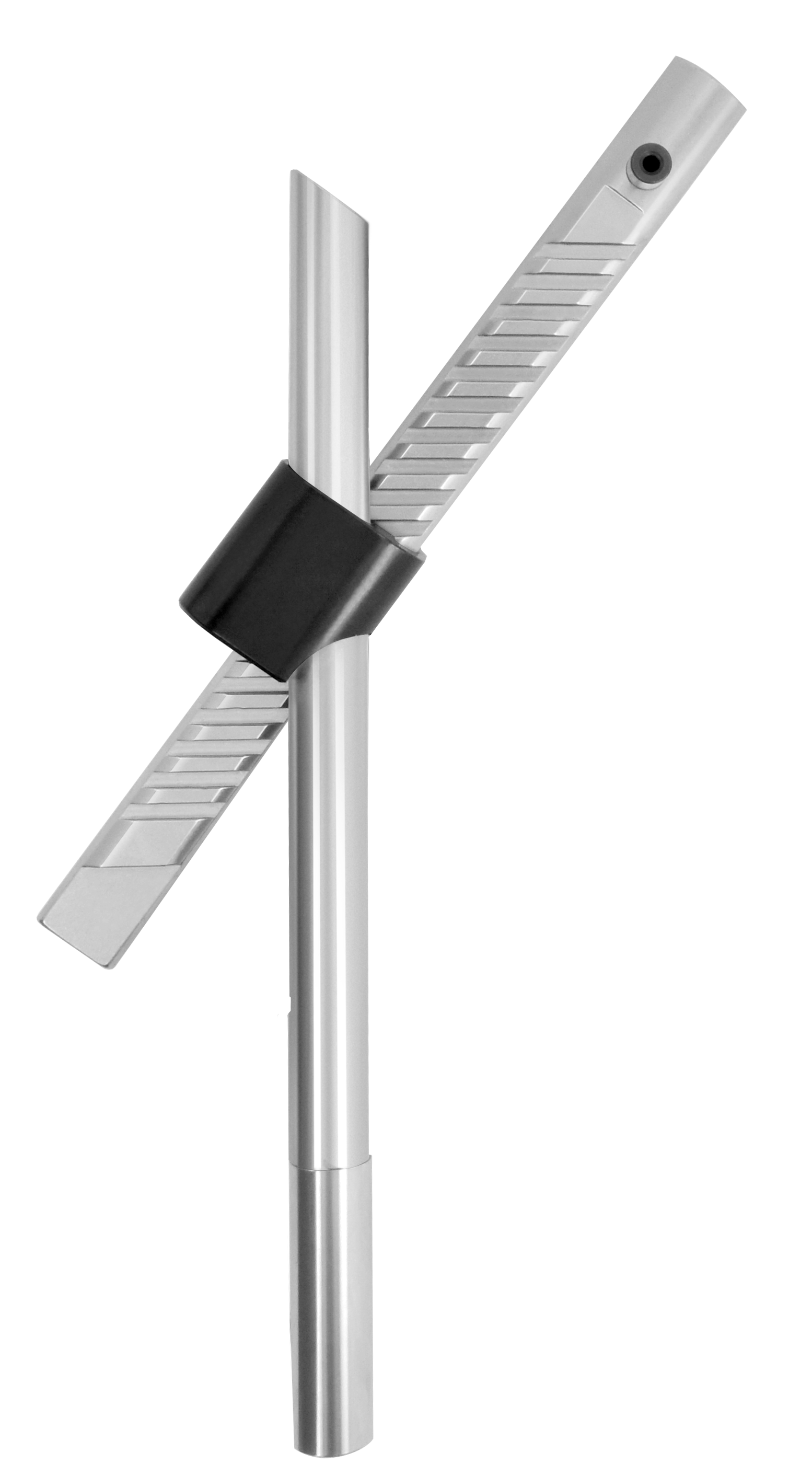

All machining needed are 90° to the parting line.

Hardened steel pre-adjusted for immediate use.

Incorporates a pre-machined hole for the angle pin

Two outer screws force the heel against the slide forming the shut off, while the central screw locks it into position and allows up to 1mm. adjusting with the mold closed.

- CG603035 – 180.000N / 18.356 Kg (40.419lb)

- CG604035 – 320.000N / 36.712 Kg (80.839lb)

- CG754049 – 320.000N / 36.712 Kg (80.839lb)

- CG604075 – 480.000N / 48.950 Kg (107.787lb)

- GI010075 – 12mm (0.472”)

- GI010090 – 15mm (0.590”)

- GI010105 – 18mm (0.708”)

Is only one lateral guide on the cam enough?

Yes, as the base will align with the cam slide perfectly, the guide is only to keep the cam slide in position.

What is the slide retainer made of?

It is a magnetic disc with a stopper that will hold the cam slide in position when the indent made by the customer on the cam slide aligns with it.

What load can the adjustable heel support?

How much can I adjust the heel?

Maximum 1.00mm (0.039”)

What stroke is achievable with the Heel Unit?

It depends on the angle pin that is used:

Where can I find the angle pins for this set?

On the GI catalogue page.