ED

Correctly installed sprung cores (following our catalogue installation instructions) can produce more than 1 million parts.

The maximum working temperature is 150°C (302°F).

Balinit C is the best coating to apply into our Sprung Cores. It provides a high superficial hardness and a low friction coefficient, i.e., it protects the part and makes it slide smoothly.

The opening of the sprung cores is a radial movement. Due to this, at the edge of the stroke, the opening is 2.5mm. (link)Here you can see a more detailed technical explanation.

Every Ejector is adjusted individually with its bushing, with a tolerance g6/H7 between them. For this reason, it is important to keep track of both pieces in pairs while handling and installing.

Yes, it is very important to give draft on the undercut, for the ED => 5º.

The shaft has to be keyed.

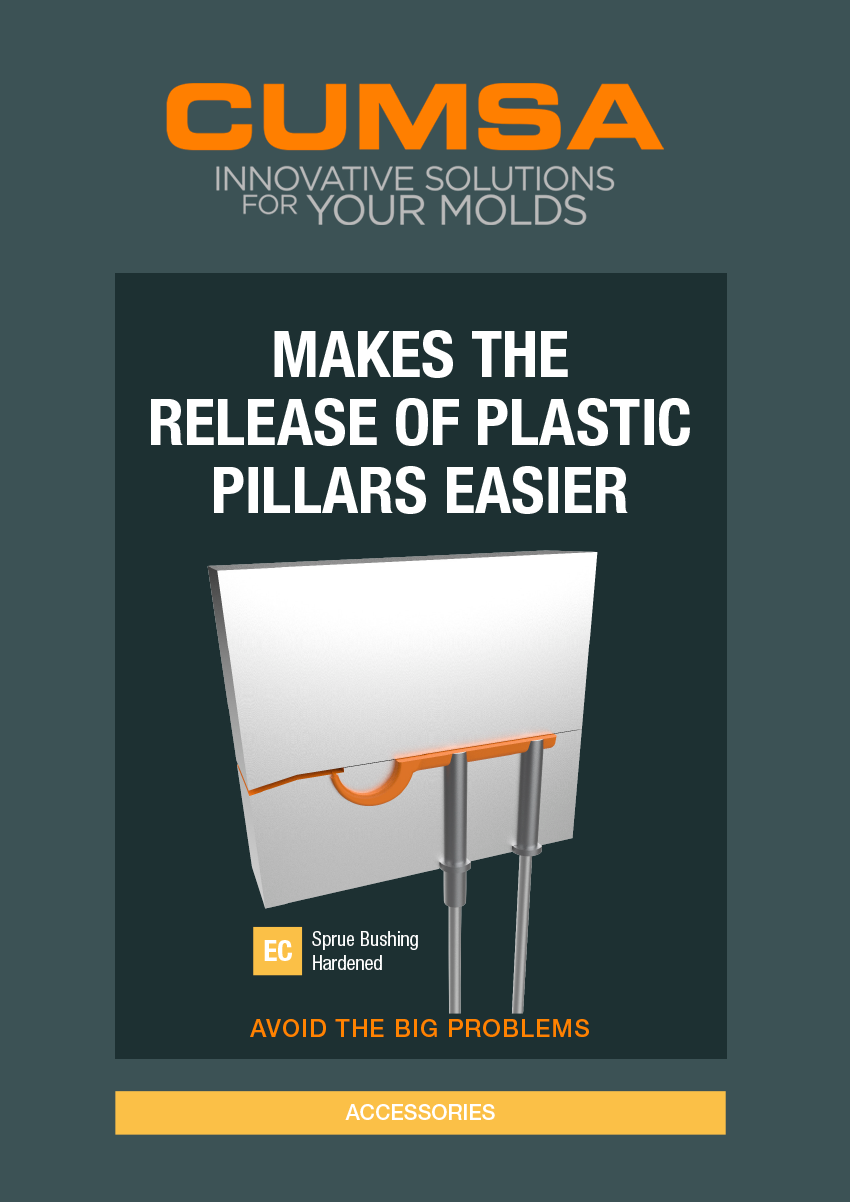

The radius of 0.10mm (0.004”), as minimum, has to be kept if the upper surface of the bushing is grinded or machined.

The shaft has to be keyed.

The radius of 0.10mm (0.004”), as minimum, has to be kept if the upper surface of the bushing is grinded or machined.

Yes, it is possible under the customer responsability. It is very important to assure the housing dimensions according to the ED or EE dimensions.