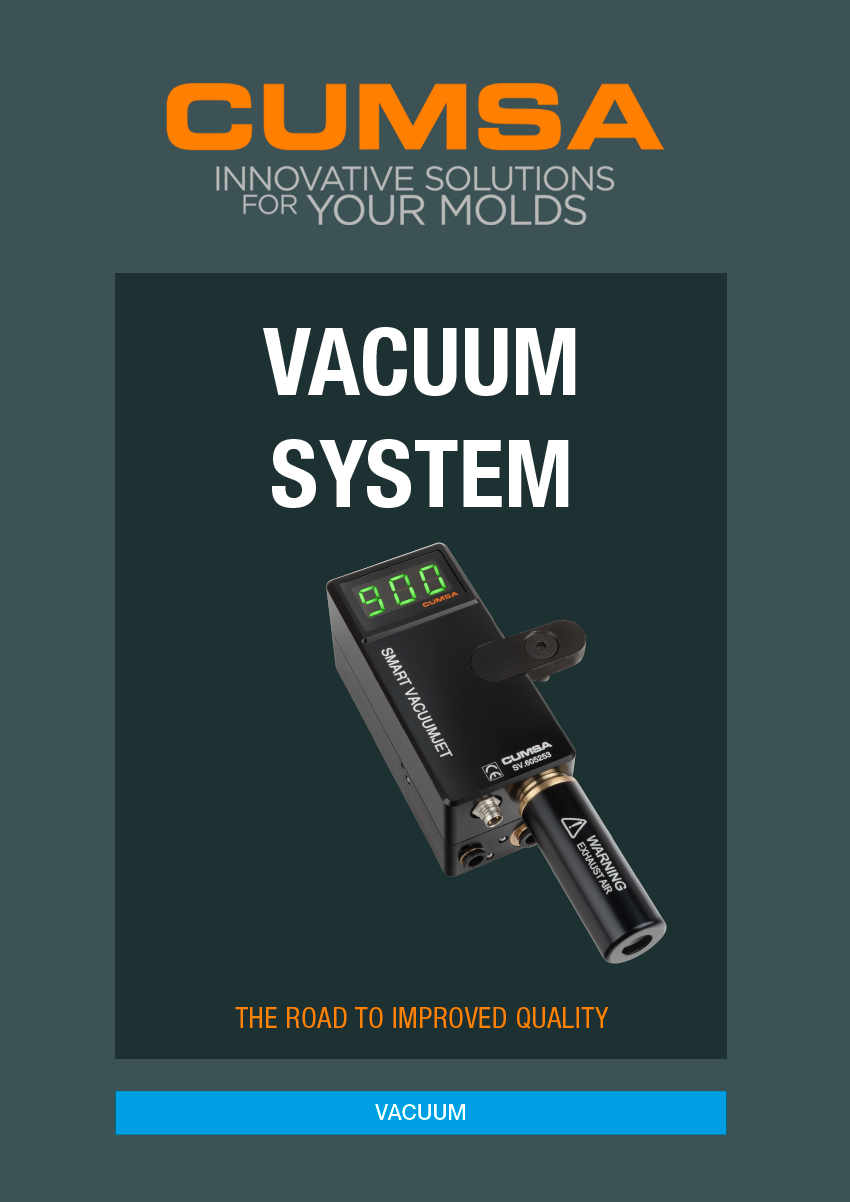

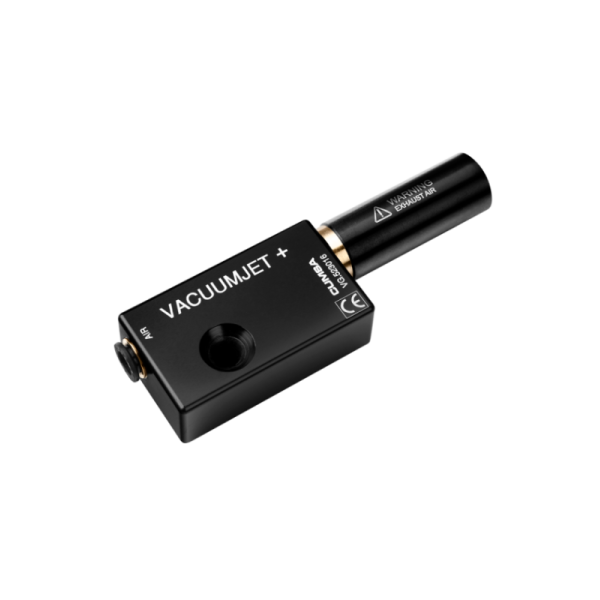

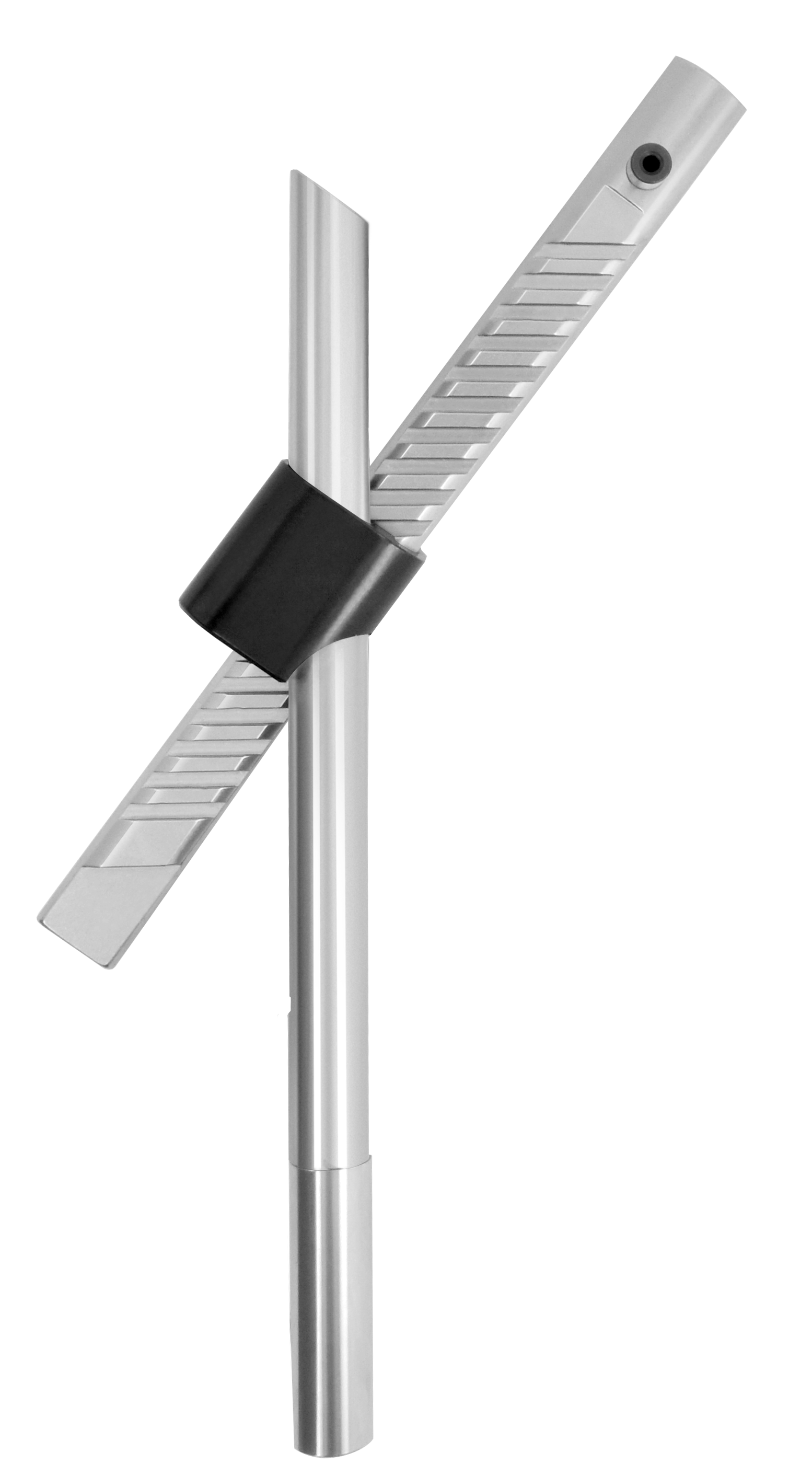

This unit itself, extracts the air from the cavity through the ejector pins.

Can be used to add more vacuuming power to the VJ (if needed).

Also can be installed with the VM, to control the vacuum level.

Read moreShow less

Can be used to add more vacuuming power to the VJ (if needed).

Also can be installed with the VM, to control the vacuum level.

Can the vacuum unit be cleaned with ultrasound?

No, because this would damage the internal components of the system.

How can Vacuum be made with this system?

Only through the clearance of the ejectors.

What is the optimal solution/recommendation to make vacuum?

Making vacuum through the VV and the clearance of the ejectors, as firstly the VV opens and withdraws instantly the air from within the cavity and at the same time make a depression inside it, and then the vacuum made through the ejectors will maintain the depression throughout the injection cycle.

How many signals (electro valves) must I have from the injection machine to control the vacuum process using a VG unit?

Just one signal.

What can be done to increase depression in the cavity if one VACUUM JET isn’t enough?

It is matter of putting 2, 3 or 4 units more. To achieve depression the key is to take more air out from the cavity than is coming in, having multiple Vacuum Jets will enable it if for some reason the cavity isn’t hermetic enough.

What to do when I don’t achieve depression in my cavity?

When we don’t achieve depression it means that the cavity isn’t hermetically closed. This can happen due to tools that have a lot of lifters and/or cam slides where closing the cavity hermetically is difficult. When this happens a solution is to apply more than one VG+, this will increase the suction power. In order to have vacuum in a cavity we need to be able to take more air out than is coming in, this can be achieved when multiple VG’s are applied in order to compensate the air that is coming in.

Is an external pump needed to make the Vacuum Unit work?

No, the unit makes vacuum through a venturing principal. The biggest advantage of this concept is that no auxiliary machines are needed, this is why this solution is very cost effective.

How many Bars are necessary?

Only 6 Bars (87 psi).

What is the maximum depression possible?

-920mBar (-13.30psi).

What is the maximum working temperature?

80°C (176°F).

Must I apply the CV’s upon all ejectors?

We recommend to apply the CV to all the ejector pins, even if they are not connected to the Vacuum channel.

Is it imperative to apply the Vacuum Seal on the parting line?

Yes it is, otherwise the air that is being taken out from the cavity will be coming in from the parting line.

Must the ejectors where the vacuum is going to be made have another tolerance?

Yes, -0.03mm (-0.0011”) to -0.04mm (-0.0016”), taking in mind the pocket is a H7, and depending on the plastic viscosity.

Which is the intensite of sound of the Vacuum Units?

| Ref | Intensity of Sound |

| VJ | 90 dB. |

| VG | 90 dB. |

| VB | 80 dB. |

| SV | 75 dB. |