Faq Sections

AE

当加速顶的内部轴与模板接触时,机构开始运行,从这一界点开始,AE上的顶针比其他顶针以两倍的速度顶出。最大额外行程为:

8mm,对应加速顶为AE031620 和 AE041620. 15mm,对应加速顶为AE052430, AE062430 和 AE082430. 20mm,对应加速顶为 AE103036 和 AE123036.

Its is not recommended as the injection pressure could damage the AE internal mechanism.

BA

BE031115: 2550N / 260Kg (572.52lb) BE041216: 2550N / 260Kg (572.52lb) BE051317: 3800N / 387Kg (852.17lb) BA/BT061418: 3800N / 387Kg (852.17lb) BA/BT081620: 5100N / 520Kg (1145.04lb) BA/BT101822: 6400N / 652Kg (1435.70lb) BA/BT122024: 7600N / 775Kg (1706.55lb)

49.03N /5Kg (11.01lb).

可以工作高达150 °C / 302°F上,高于这个温度内部弹簧可能失效。

BE

BE031115: 2550N / 260Kg (572.52lb) BE041216: 2550N / 260Kg (572.52lb) BE051317: 3800N / 387Kg (852.17lb) BA/BT061418: 3800N / 387Kg (852.17lb) BA/BT081620: 5100N / 520Kg (1145.04lb) BA/BT101822: 6400N / 652Kg (1435.70lb) BA/BT122024: 7600N / 775Kg (1706.55lb)

可以工作高达150 °C / 302°F上,高于这个温度内部弹簧可能失效。

49.03N /5Kg (11.01lb).

BG

Show More >>

15º and 20º.

由选用斜顶长度和斜顶导套的角度决定:

| Ref | Angle Pin | Stroke |

| BG.423016-15 | GI.016115 | 19.8mm. (0.780") |

| GI.016135 | 25mm. (0.984") | |

| GI.016160 | 25mm. (1.240") | |

| BG.423016-20 | GI.016115 | 26mm. (1.024") |

| GI.016135 | 32.8mm. (1.291") | |

| GI.016160 | 41.4mm. (1.630") | |

| BG.504020-15 | GI.020140 | 24.2mm. (0.953") |

| GI.020165 | 30.7mm. (1.209") | |

| GI.020190 | 37.1mm. (1.461") | |

| BG.504020-20 | GI.020140 | 31.7mm. (1.248") |

| GI.020165 | 40.2mm. (1.583") | |

| GI.020190 | 48.7mm. (1.917") | |

| BG.554024-15 | GI.024170 | 30.4mm. (1.197") |

| GI.024195 | 36.9mm. (1.453") | |

| GI.024220 | 43.3mm. (1.705") | |

| BG.554024-20 | GI.024170 | 39.9mm. (1.571") |

| GI.024195 | 48.4mm. (1.906") | |

| GI.024220 | 57mm. (2.244") | |

| BG.655028-15 | GI.028200 | 36.4mm. (1.433") |

| GI. 028225 | 42.9mm. (1.689") | |

| GI. 028250 | 49.3mm. (1.941") | |

| BG. 655028-20 | GI. 028200 | 47.8mm. (1.571") |

| GI. 028225 | 56.3mm. (1.906") | |

| GI. 028250 | 64.9mm. (2.244") |

起到只用一个螺丝便可拆除斜顶导套的作用,同时也是用于固定斜顶导在模具上。

Show More >>

BM

| Ref | Numbers | Line |

| PM...... | 0.15-0.20mm. (0.006-0.008") | 0.50-0.60mm. (0.019-0.024") |

| Ref | Triangle |

| BM...... | 0.20-0.25mm. (0.08-0.010") |

| Ref | Arrow |

| PM...... BM...... | M3.5x0.6mm. |

Yes, on our catalogo page we indicate the size of the hole (E dimension) to be made before installing, the date stamp can then be removed using the appropiate ejector.

BT

BE031115: 2550N / 260Kg (572.52lb) BE041216: 2550N / 260Kg (572.52lb) BE051317: 3800N / 387Kg (852.17lb) BA/BT061418: 3800N / 387Kg (852.17lb) BA/BT081620: 5100N / 520Kg (1145.04lb) BA/BT101822: 6400N / 652Kg (1435.70lb) BA/BT122024: 7600N / 775Kg (1706.55lb)

可以工作高达150 °C / 302°F上,高于这个温度内部弹簧可能失效。

49.03N /5Kg (11.01lb).

CC

Show More >>

我们建议电子计数器在60 °C / 140°F.下工作。

计数器预计将持续5年,以它工作24个小时/7天/12个月计算。在非常热的环境下会缩短电池的寿命。

当安装在模具里时计数器电池开始工作。

Show More >>

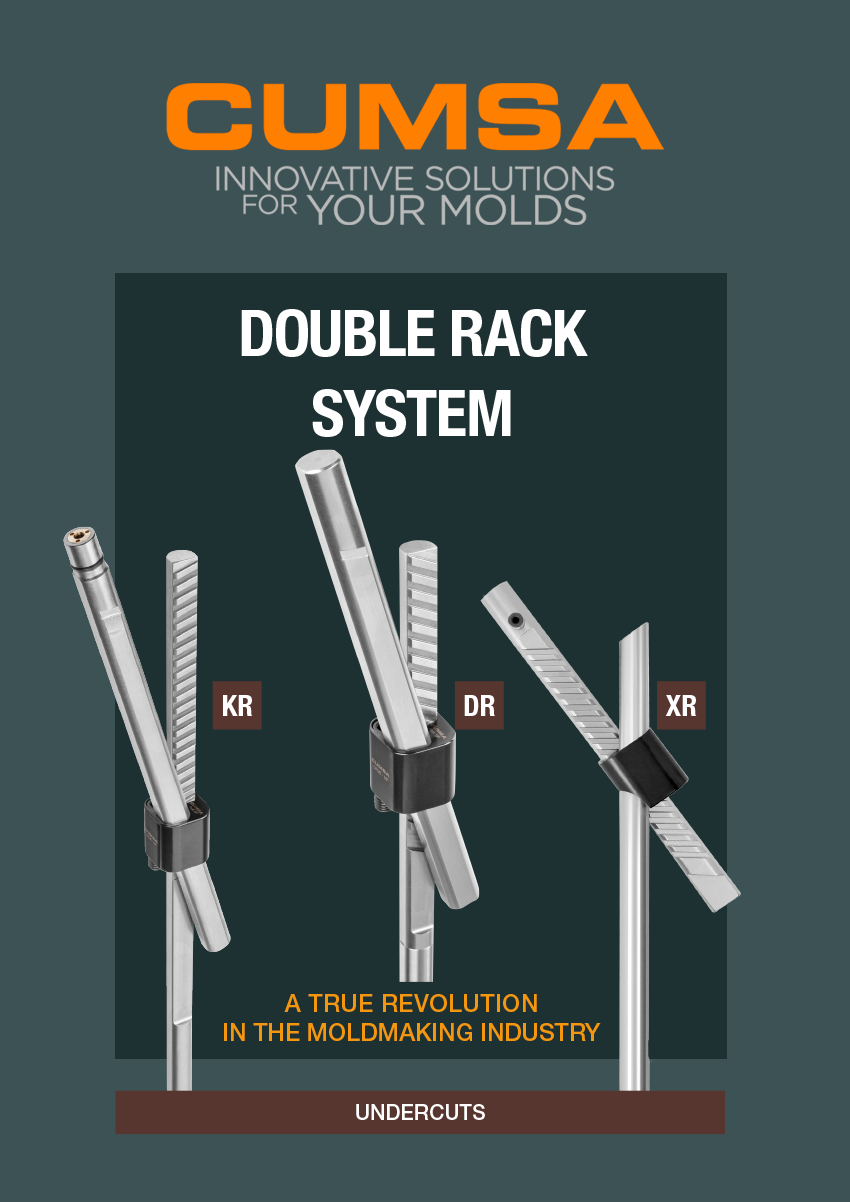

DR

DR16: 1650 N / 168Kg (371lb) DR22 / DR28: 2600N / 265Kg (584lb) DR34: 4950N / 504Kg (1112lb) DR40 / DR46: 9950N / 1014Kg (2236lb)

For the DR16: M6x0,75 For the DR22: M8x0,75 For the DR28: M9x0,75 For the DR34: M9x0,75 For the DR40: M12x1 For the DR46: M16x1

ED

Show More >>

一个弹性斜顶正确安装可以产生超过100 万个模次没有问题的。

最大工作温度是150°C / 302°F。

Balinit C是应用在我们弹簧芯上最好的涂层,它提供了一个高表面硬度和低摩擦系数,它保护了零件和使其顺畅的滑行。

Show More >>

EE

Show More >>

一个弹性斜顶正确安装可以产生超过100 万个模次没有问题的。

最大工作温度150°C / 302°F。

Balinit C是应用在我们弹簧芯上最好的涂层,它提供了一个高表面硬度和低摩擦系数,它保护了零件和使其顺畅的滑行。

Show More >>

FA

Show More >>

通常日期章最高工作温度可达150 °C / 302°F.

| Ref | Numbers | Arrow |

| FA04.... IA22…. | 0.15mm. (0.006") | 0.35mm. (0.014") |

| FA05.... IA30 | 0.15mm. (0.006") | 0.40mm. (0.016") |

| FA06.... IA32.... | 0.15mm. (0.006") | 0.40mm. (0.016") |

| FA08.... IA47.... | 0.15mm. (0.006") | 0.40mm. (0.016") |

| FA10.... IA57.... | 0.15mm. (0.006") | 0.50mm. (0.020") |

| FA12.... IA67.... | 0.15mm. (0.006") | 0.50mm. (0.020") |

| FA16.... IA87.... | 0.15mm. (0.006") | 0.70mm. (0.028") |

| FA20.... IA107... | 0.15mm. (0.006") | 0.70mm. (0.028") |

| Ref | Arrow |

| FA04.... IA22.... | M1.6x0.35mm. |

| FA05.... IA30.... | M1.6x0.35mm. |

| FA06.... IA32.... | M2.5x0.45mm. |

| FA08.... IA47.... | M3.0x0.50mm. |

| FA10.... IA57.... | M3.0x0.50mm. |

| FA12.... IA67.... | M3.5x0.60mm. |

| FA16.... IA87.... | M3.5x0.60mm. |

| FA20.... IA10.... | M3.5x0.60mm. |

Show More >>

FD

| Ref | Numbers | Line | Triangle |

| FD08.... FD12.... FD16.... | 0.15mm. (0.006") | 0.7mm. (0.028") | 0.15mm. (0.006") |

是的,我们所有的日期章系列都可以按照要求雕刻。

Yes, on our catalogo page we indicate the size of the hole (E dimension) to be made before installing, the date stamp can then be removed using the appropiate ejector.

FP

Show More >>

通常日期章最高工作温度可达150 °C / 302°F.

| Ref | Numbers | Arrow |

| FP04.... IA22…. | 0.15mm. (0.006") | 0.35mm. (0.014") |

| FP05.... IA30 | 0.15mm. (0.006") | 0.40mm. (0.016") |

| FP06.... IA32.... | 0.15mm. (0.006") | 0.40mm. (0.016") |

| FP08.... IA47.... | 0.15mm. (0.006") | 0.40mm. (0.016") |

| FP10.... IA57.... | 0.15mm. (0.006") | 0.50mm. (0.020") |

| FP12.... IA67.... | 0.15mm. (0.006") | 0.50mm. (0.020") |

| FP16.... IA87.... | 0.15mm. (0.006") | 0.70mm. (0.028") |

| FP20.... IA107... | 0.15mm. (0.006") | 0.70mm. (0.028") |

| Ref | Arrow |

| FP04.... IA22.... | M1.6x0.35mm. |

| FP05.... IA30.... | M1.6x0.35mm. |

| FP06.... IA32.... | M2.5x0.45mm. |

| FP08.... IA47.... | M3.0x0.50mm. |

| FP10.... IA57.... | M3.0x0.50mm. |

| FP12.... IA67.... | M3.5x0.60mm. |

| FP16.... IA87.... | M3.5x0.60mm. |

| FP20.... IA10.... | M3.5x0.60mm. |

Show More >>

FU

Show More >>

通常迷你日期章工作温度高达150 °C / 302°F。

| Ref | Numbers | Arrow |

| FU03.... | 0.10-0.20mm. (0.004-0.007") | 0.35-0.50mm. (0.013-0.019") |

| Ref | Arrow |

| FU03.... IU03.... | M1.6x0.35mm. |

Show More >>

FX

Show More >>

| Ref | Screwdriver |

| FX04.... IX21.... | 1.2mm x 0.2mm. (0.047" x 0.0079") |

| FX05.... IX31.... | 1.5mm. x 0.25mm. (0.059" x 0.0098") |

| FX06.... IX32.... | 1.8mm. x 0.3mm. (0.071" x 0.0118") |

| FX08.... IX47.... | 2mm. x 0.4mm. (0.079" x 0.0157") |

| FX10.... IX57.... | 2.5mm. x 0.4mm. (0.098" x 0.0157") |

| FX12.... IX67.... | 3mm. x 0.5mm. (0.118" x 0.0197") |

是的,我们所有的日期章系列都可以按照要求雕刻。

Yes, on our catalogue page we indicate the size of the hole (E dimension) to be made before installing, the date stamp can then be removed using the appropiate ejector.

On the smaller diametres (6) extra care needs to be taken to remove the part slowly, knocking softly to avoid damage to the internal mechanisms.

On the smaller diametres (6) extra care needs to be taken to remove the part slowly, knocking softly to avoid damage to the internal mechanisms.

Show More >>

GR

Show More >>

10º and 15º.

由选用斜顶长度和斜顶导套的角度决定:

| Ref | Angle Pin | Stroke |

| GR.182622-10 | GI.010075 | 7.5mm. (0.295") |

| GI.010090 | 10.2mm. (0.402") | |

| GI.010105 | 12.8mm. (0.504") | |

| GR.182622-15 | GI.010075 | 11.2mm. (0.441") |

| GI.010090 | 15.1mm. (0.594") | |

| GI.010105 | 19mm. (0.748") | |

| GR.222826-10 | GI.012095 | 10.6mm. (0.417") |

| GI.012110 | 13.2mm. (0.520") | |

| GI.012130 | 16.6mm. (0.654") | |

| GR.222826-15 | GI.012095 | 15.6mm. (0.614") |

| GI.012110 | 19.5mm. (0.768") | |

| GI.012130 | 20.5mm. (0.807") | |

| GR.283432-10 | GI.016115 | 12.7mm. (0.500") |

| GI.016135 | 16.1mm. (0.634") | |

| GI.016160 | 20.5mm. (0.807") | |

| GR.283432-15 | GI.016115 | 18.8mm. (0.740") |

| GI.016135 | 23.9mm. (0.941") | |

| GI.016160 | 30.4mm. (1.197") | |

| GR.344038-10 | GI.020140 | 15.4mm. (0.606") |

| GI.020165 | 19.9mm. (0.783") | |

| GI.020190 | 24.3mm. (0.957") | |

| GR.344038-15 | GI.020140 | 23.1mm. (0.909") |

| GI.020165 | 29.6mm. (1.165") | |

| GI.020190 | 36mm. (1.417") | |

| GR.424546-10 | GI.024170 | 19.6mm. (0.772") |

| GI.024195 | 23.9mm. (0.941") | |

| GI.024220 | 28.1mm. (1.106") | |

| GR.424546-15 | GI.024170 | 29.1mm. (1.146") |

| GI.024195 | 35.3mm. (1.390") | |

| GI.024220 | 41.7mm. (1.642") | |

| GR.465050-10 | GI.028200 | 23.6mm. (0.929") |

| GI.028225 | 28mm. (1.102") | |

| GI.028250 | 32.3mm. (1.1272") | |

| GR.465050-15 | GI.028200 | 35mm. (1.378") |

| GI.028225 | 41.5mm. (1.634") | |

| GI.028250 | 48mm. (1.890") |

起到固定斜顶导套防止其旋转。

Show More >>

GS

Show More >>

GS.226616可用于500 x 500 的三板模

GS.368619可用于800 x 800 的三板模

GS.421024可用于1000 x 1000 的三板模

GS.368619可用于800 x 800 的三板模

GS.421024可用于1000 x 1000 的三板模

当要求绝对的承受力和平衡性时,CUMSA推荐使用4个。

不建议这种做法,顶针板的移动会伴随很大的承载力,因为很多机构都是附属在顶针板,靠顶针板带动完成,比如:塑料收缩率、顶针、斜顶、脱模板等。

Show More >>

IA

Show More >>

通常日期章最高工作温度可达150 °C / 302°F.

| Ref | Numbers | Arrow |

| FA04.... IA22…. | 0.15mm. (0.006") | 0.35mm. (0.014") |

| FA05.... IA30 | 0.15mm. (0.006") | 0.40mm. (0.016") |

| FA06.... IA32.... | 0.15mm. (0.006") | 0.40mm. (0.016") |

| FA08.... IA47.... | 0.15mm. (0.006") | 0.40mm. (0.016") |

| FA10.... IA57.... | 0.15mm. (0.006") | 0.50mm. (0.020") |

| FA12.... IA67.... | 0.15mm. (0.006") | 0.50mm. (0.020") |

| FA16.... IA87.... | 0.15mm. (0.006") | 0.70mm. (0.028") |

| FA20.... IA107... | 0.15mm. (0.006") | 0.70mm. (0.028") |

| Ref | Arrow |

| FA04.... IA22.... | M1.6x0.35mm. |

| FA05.... IA30.... | M1.6x0.35mm. |

| FA06.... IA32.... | M2.5x0.45mm. |

| FA08.... IA47.... | M3.0x0.50mm. |

| FA10.... IA57.... | M3.0x0.50mm. |

| FA12.... IA67.... | M3.5x0.60mm. |

| FA16.... IA87.... | M3.5x0.60mm. |

| FA20.... IA10.... | M3.5x0.60mm. |

Show More >>

IX

Show More >>

</tr

| Ref | Screwdriver |

| FX04.... IX21.... |

1.2mm x 0.2mm. (0.047" x 0.0079") |

| FX05.... IX31.... |

1.5mm. x 0.25mm. (0.059" x 0.0098") |

| FX06.... IX32.... |

1.8mm. x 0.3mm. (0.071" x 0.0118") |

| FX08.... IX47.... |

2mm. x 0.4mm. (0.079" x 0.0157") |

| FX10.... IX57.... |

2.5mm. x 0.4mm. (0.098" x 0.0157") |

| FX12.... IX67.... |

3mm. x 0.5mm. (0.118" x 0.0197") |

是的,我们所有的日期章系列都可以按照要求雕刻。

| Ref | Numbers | Line |

| FX04.... IX21.... | 0,15mm. (0.006") | 0,35mm. (0.014") |

| FX05.... IX31.... | 0,15mm. (0.006") | 0,40mm. (0.016") |

| FX06.... IX32.... | 0,15mm. (0.006") | 0,40mm. (0.016") |

| FX08.... IX47.... | 0,15mm. (0.006") | 0,40mm. (0.016") |

| FX10.... IX57.... | 0,15mm. (0.006") | 0,50mm. (0.020") |

| FX12.... IX67.... | 0,15mm. (0.006") | 0,50mm. (0.020") |

Show More >>

KR

KR22 / KR28: 2600N / 265Kg (584lb) KR34: 4950N / 504Kg (1112lb)

For the KR22: M8x0,75 For the KR28: M9x0,75 For the KR34: M9x0,75 For the KR58: M18x2,5 For the KR76: M24x3

See it here.

LR

Show More >>

最大顶出速度为每分钟30米。

1961.20N / 200Kg (440.40lb) per unit.

Yes, if the plates are correctly aligned, the second movement can be free.

Show More >>

MG

MG121648: 50.000N / 5.099 Kg (11.241 lb). MG201648: 90.000N / 9.187 Kg (20.253 lb).

Show More >>

最大值0.6毫米/0.024英寸

行程为4毫米/0.157英寸

Show More >>

NP

点击此处下载 新的抽真空系统用户手册!

200°C (392°F).

是的,需要-0.03mm(-0.0011")至-0.04mm(-0.0016")的间隙,请注意是H7配合,间隙的大小取决于塑性粘度。

NR

点击此处下载 新的抽真空系统用户手册!

200°C (392°F).

是的,需要-0.03mm(-0.0011")至-0.04mm(-0.0016")的间隙,请注意是H7配合,间隙的大小取决于塑性粘度。

PF

Show More >>

一个弹性斜顶正确安装可以产生超过100 万个模次没有问题的。

最高工作温度是150°C / 302°F。

Balinit C是应用在我们弹簧芯上最好的涂层,它提供了一个高表面硬度和低摩擦系数,它保护了零件和使其顺畅的滑行。

Show More >>

PH

点击此处下载 新的抽真空系统用户手册!

200°C (392°F).

是的,需要-0.03mm(-0.0011")至-0.04mm(-0.0016")的间隙,请注意是H7配合,间隙的大小取决于塑性粘度。

PR

PW

Show More >>

一个弹性斜顶正确安装可以产生超过100 万个模次没有问题的。

弹性斜顶的开放是个弧度运动,由于这个原因,在顶端的行程是3.5毫米/0.138”,4.5毫米/0.177”和5.5毫米/0.217”,取决于不同的型号(目录中的K值)。 在这里你可以看到更详细的技术解析。

任何弹性斜顶产品不推荐焊接,焊接会使其暴露在高温而影响处理区域,因此而影响弹簧钢的弹性。

Show More >>

PX

Show More >>

一个弹性斜顶正确安装可以产生超过100 万个模次没有问题的。

La abertura de las pinzas flexibles es un movimiento radial. En relación a esto, la abertura es de 4.5mm (0.177”).

任何弹性斜顶产品不推荐焊接,焊接会使其暴露在高温而影响处理区域,因此而影响弹簧钢的弹性。

Show More >>

RM

SU

Show More >>

不能,它是靠一个锥体刚好与凹槽并合,起到滑块固定的作用。

行程分别为: 3mm, 4mm and 5mm. (0.118”, 0.157” and 0.197”)

可以。如果我们的标准镶件不合适,客户需要自行做一个更大的镶件,可以单独购买基座。

Show More >>

SV

Show More >>

三种方式可以抽真空:

通过抽气阀和顶针间隙同时抽气。 仅通过抽气阀抽气。 仅通过顶针间隙抽气。

通过抽气阀和顶针间隙同时抽气,因为首先通过气阀打开迅速抽出模腔内空气,模腔内形成负压状态,然后在注塑的同时通过顶针间隙维持负压。

2个独立信号:

一个用于控制抽气阀;它必须在注塑前打开和关闭气动活塞。它必须与注塑周期同步。 另一个用于控制抽气。根据顶针的直径及间隙的大小,抽气回路应当打开和关闭,因为如果很多气体从顶针间隙抽气,那注塑时很可能跑胶进去;如果顶针很小或者间隙很小,那抽气回路可以一直开着。

Show More >>

UU

Show More >>

不能,它是靠一个锥体刚好与凹槽并合,起到滑块固定的作用。

行程分别为: 3mm, 4mm and 5mm. (0.118”, 0.157” and 0.197”)

可以。如果我们的标准镶件不合适,客户需要自行做一个更大的镶件,可以单独购买基座。

Show More >>

VB

Show More >>

三种方式可以抽真空:

通过抽气阀和顶针间隙同时抽气。 仅通过抽气阀抽气。 仅通过顶针间隙抽气。

通过抽气阀和顶针间隙同时抽气,因为首先通过气阀打开迅速抽出模腔内空气,模腔内形成负压状态,然后在注塑的同时通过顶针间隙维持负压。

2个独立信号:

一个用于控制抽气阀;它必须在注塑前打开和关闭气动活塞。它必须与注塑周期同步。 另一个用于控制抽气。根据顶针的直径及间隙的大小,抽气回路应当打开和关闭,因为如果很多气体从顶针间隙抽气,那注塑时很可能跑胶进去;如果顶针很小或者间隙很小,那抽气回路可以一直开着。

Show More >>

VG

Show More >>

仅通过顶针间隙抽气。

通过抽气阀和顶针间隙同时抽气,因为首先通过气阀打开迅速抽出模腔内空气,模腔内形成负压状态,然后在注塑的同时通过顶针间隙维持负压。

2个独立信号:

一个用于控制抽气阀;它必须在注塑前打开和关闭气动活塞。它必须与注塑周期同步。 另一个用于控制抽气。根据顶针的直径及间隙的大小,抽气回路应当打开和关闭,因为如果很多气体从顶针间隙抽气,那注塑时很可能跑胶进去;如果顶针很小或者间隙很小,那抽气回路可以一直开着。

Show More >>

VJ

Show More >>

三种方式可以抽真空:

通过抽气阀和顶针间隙同时抽气。 仅通过抽气阀抽气。 仅通过顶针间隙抽气。

通过抽气阀和顶针间隙同时抽气,因为首先通过气阀打开迅速抽出模腔内空气,模腔内形成负压状态,然后在注塑的同时通过顶针间隙维持负压。

2个独立信号:

一个用于控制抽气阀;它必须在注塑前打开和关闭气动活塞。它必须与注塑周期同步。 另一个用于控制抽气。根据顶针的直径及间隙的大小,抽气回路应当打开和关闭,因为如果很多气体从顶针间隙抽气,那注塑时很可能跑胶进去;如果顶针很小或者间隙很小,那抽气回路可以一直开着。

Show More >>

VM

Show More >>

80°C (176°F).

当我们的负压值不高时,这意味着模腔没有气密封闭。 可能是由于有大量的斜顶和滑块,这样我们想要密封地封闭模腔是困难的。当发生这种情况的解决方案是应用一个以上的抽真空机构(VJ),这将增加吸力。为了实现真空状态的模腔,我们需要能够抽取更多的空气出来,使用多个VJ这样以便补偿在抽的过程中不断从缝隙中渗透进去的空气。

不, 产生真空主要是通过这个机构本身来实现的.这一概念的最大优点是,不需要辅助设备,这就是为什么这个解决方案是非常符合成本效益。

Show More >>

WL

Depends on the angle and the ejection stroke, please review this table to have the approximate values:

| Demolding Angles |

| Demolding Strokes | 1º | 2º | 3º | 4º | 5º | 6º |

| 5 mm. (0,197") | 0,09 mm. (0,003") | 0,17 mm. (0,007") | 0,26 mm. (0,01") | 0,35 mm. (0,014") | 0,44 mm. (0,017") | 0,53 mm. (0,021") |

| 10 mm. (0,394") | 0,17 mm. (0,007") | 0,35 mm. (0,014") | 0,52 mm. (0,021") | 0,7 mm. (0,028") | 0,87 mm. (0,034") | 1,05 mm. (0,041") |

| 15 mm. (0,591") | 0,26 mm. (0,01") | 0,52 mm. (0,021") | 0,79 mm. (0,031") | 1,05 mm. (0,041") | 1,31 mm. (0,052") | 1,58 mm. (0,062") |

| 20 mm. (0,787") | 0,35 mm. (0,014") | 0,7 mm. (0,027") | 1,05 mm. (0,041") | 1,4 mm. (0,055") | 1,75 mm. (0,069") | 2,1 mm. (0,083") |

| 25 mm. (0,984") | 0,44 mm. (0,017") | 0,87 mm. (0,034") | 1,31 mm. (0,052") | 1,75 mm. (0,069") | 2,19 mm. (0,086") | 2,63 mm. (0,103") |

| 30 mm. (1,181") | 0,52 mm. (0,021") | 1,05 mm. (0,041") | 1,57 mm. (0,062") | 2,1 mm. (0,083") | 2,62 mm. (0,103") | 3,15 mm. (0,124") |

| 35 mm. (1,378") | 0,61 mm. (0,024") | 1,22 mm. (0,048") | 1,83 mm. (0,072") | 2,45 mm. (0,096") | 3,06 mm. (0,121") | 3,68 mm. (0,145") |

| 40 mm. (1,575") | 0,7 mm. (0,028") | 1,4 mm. (0,055") | 2,1 mm. (0,083") | 2,8 mm. (0,11") | 3,5 mm. (0,138") | 4,2 mm. (0,166") |

| 45 mm. (1,772") | 0,79 mm. (0,031") | 1,57 mm. (0,062") | 2,36 mm. (0,093") | 3,15 mm. (0,124") | 3,94 mm. (0,155") | 4,73 mm. (0,186") |

| 50 mm. (1,969") | 0,87 mm. (0,034") | 1,75 mm. (0,069") | 2,62 mm. (0,103") | 3,5 mm. (0,138") | 4,37 mm. (0,172") | 5,26 mm. (0,207") |

| 55 mm. (2,165") | 0,96 mm. (0,038") | 1,92 mm. (0,076") | 2,88 mm. (0,113") | 3,85 mm. (0,151") | 4,81 mm. (0,189") | 5,78 mm. (0,228") |

| 60 mm. (2,362") | 1,05 mm. (0,041") | 2,1 mm. (0,082") | 3,14 mm. (0,124") | 4,2 mm. (0,165") | 5,25 mm. (0,207") | 6,31 mm. (0,248") |

| 65 mm. (2,559") | 1,13 mm. (0,045") | 2,27 mm. (0,089") | 3,41 mm. (0,134") | 4,55 mm. (0,179") | 5,69 mm. (0,224") | 6,83 mm. (0,269") |

| 70 mm. (2,756") | 1,22 mm. (0,048") | 2,44 mm. (0,096") | 3,67 mm. (0,144") | 4,89 mm. (0,193") | 6,12 mm. (0,241") | 7,36 mm. (0,29") |

| 75 mm. (2,953") | 1,31 mm. (0,052") | 2,62 mm. (0,103") | 3,93 mm. (0,155") | 5,24 mm. (0,206") | 6,56 mm. (0,258") | 7,88 mm. (0,31") |

| 80 mm. (3,15") | 1,4 mm. (0,055") | 2,79 mm. (0,11") | 4,19 mm. (0,165") | 5,59 mm. (0,22") | 7 mm. (0,276") | 8,41 mm. (0,331") |

| 85 mm. (3,346") | 1,48 mm. (0,058") | 2,97 mm. (0,117") | 4,45 mm. (0,175") | 5,94 mm. (0,234") | 7,44 mm. (0,293") | 8,93 mm. (0,352") |

| 90 mm. (3,543") | 1,57 mm. (0,062") | 3,14 mm. (0,124") | 4,72 mm. (0,186") | 6,29 mm. (0,248") | 7,87 mm. (0,31") | 9,46 mm. (0,372") |

| 95 mm. (3,74") | 1,66 mm. (0,065") | 3,32 mm. (0,131") | 4,98 mm. (0,196") | 6,64 mm. (0,262") | 8,31 mm. (0,327") | 9,98 mm. (0,393") |

| 100 mm. (3,937") | 1,75 mm. (0,069") | 3,49 mm. (0,137") | 5,24 mm. (0,206") | 6,99 mm. (0,275") | 8,75 mm. (0,344") | 10,51 mm. (0,414") |

| 105 mm. (4,134") | 1,83 mm. (0,072") | 3,67 mm. (0,144") | 5,5 mm. (0,217") | 7,34 mm. (0,289") | 9,19 mm. (0,362") | 11,04 mm. (0,434") |

| 110 mm. (4,331") | 1,92 mm. (0,076") | 3,84 mm. (0,151") | 5,76 mm. (0,227") | 7,69 mm. (0,303") | 9,62 mm. (0,379") | 11,56 mm. (0,455") |

| 115 mm. (4,528") | 2,01 mm. (0,079") | 4,02 mm. (0,158") | 6,03 mm. (0,237") | 8,04 mm. (0,317") | 10,06 mm. (0,396") | 12,09 mm. (0,476") |

| 120 mm. (4,724") | 2,09 mm. (0,083") | 4,19 mm. (0,165") | 6,29 mm. (0,248") | 8,39 mm. (0,33") | 10,5 mm. (0,413") | 12,61 mm. (0,497") |

| 125 mm. (4,921") | 2,18 mm. (0,086") | 4,37 mm. (0,172") | 6,55 mm. (0,258") | 8,74 mm. (0,344") | 10,94 mm. (0,431") | 13,14 mm. (0,517") |

WP

Depends on the angle and the ejection stroke, please review this table to have the approximate values:

| Demolding Angles |

| Demolding Strokes | 1º | 2º | 3º | 4º | 5º | 6º |

| 5 mm. (0,197") | 0,09 mm. (0,003") | 0,17 mm. (0,007") | 0,26 mm. (0,01") | 0,35 mm. (0,014") | 0,44 mm. (0,017") | 0,53 mm. (0,021") |

| 10 mm. (0,394") | 0,17 mm. (0,007") | 0,35 mm. (0,014") | 0,52 mm. (0,021") | 0,7 mm. (0,028") | 0,87 mm. (0,034") | 1,05 mm. (0,041") |

| 15 mm. (0,591") | 0,26 mm. (0,01") | 0,52 mm. (0,021") | 0,79 mm. (0,031") | 1,05 mm. (0,041") | 1,31 mm. (0,052") | 1,58 mm. (0,062") |

| 20 mm. (0,787") | 0,35 mm. (0,014") | 0,7 mm. (0,027") | 1,05 mm. (0,041") | 1,4 mm. (0,055") | 1,75 mm. (0,069") | 2,1 mm. (0,083") |

| 25 mm. (0,984") | 0,44 mm. (0,017") | 0,87 mm. (0,034") | 1,31 mm. (0,052") | 1,75 mm. (0,069") | 2,19 mm. (0,086") | 2,63 mm. (0,103") |

| 30 mm. (1,181") | 0,52 mm. (0,021") | 1,05 mm. (0,041") | 1,57 mm. (0,062") | 2,1 mm. (0,083") | 2,62 mm. (0,103") | 3,15 mm. (0,124") |

| 35 mm. (1,378") | 0,61 mm. (0,024") | 1,22 mm. (0,048") | 1,83 mm. (0,072") | 2,45 mm. (0,096") | 3,06 mm. (0,121") | 3,68 mm. (0,145") |

| 40 mm. (1,575") | 0,7 mm. (0,028") | 1,4 mm. (0,055") | 2,1 mm. (0,083") | 2,8 mm. (0,11") | 3,5 mm. (0,138") | 4,2 mm. (0,166") |

| 45 mm. (1,772") | 0,79 mm. (0,031") | 1,57 mm. (0,062") | 2,36 mm. (0,093") | 3,15 mm. (0,124") | 3,94 mm. (0,155") | 4,73 mm. (0,186") |

| 50 mm. (1,969") | 0,87 mm. (0,034") | 1,75 mm. (0,069") | 2,62 mm. (0,103") | 3,5 mm. (0,138") | 4,37 mm. (0,172") | 5,26 mm. (0,207") |

| 55 mm. (2,165") | 0,96 mm. (0,038") | 1,92 mm. (0,076") | 2,88 mm. (0,113") | 3,85 mm. (0,151") | 4,81 mm. (0,189") | 5,78 mm. (0,228") |

| 60 mm. (2,362") | 1,05 mm. (0,041") | 2,1 mm. (0,082") | 3,14 mm. (0,124") | 4,2 mm. (0,165") | 5,25 mm. (0,207") | 6,31 mm. (0,248") |

| 65 mm. (2,559") | 1,13 mm. (0,045") | 2,27 mm. (0,089") | 3,41 mm. (0,134") | 4,55 mm. (0,179") | 5,69 mm. (0,224") | 6,83 mm. (0,269") |

| 70 mm. (2,756") | 1,22 mm. (0,048") | 2,44 mm. (0,096") | 3,67 mm. (0,144") | 4,89 mm. (0,193") | 6,12 mm. (0,241") | 7,36 mm. (0,29") |

| 75 mm. (2,953") | 1,31 mm. (0,052") | 2,62 mm. (0,103") | 3,93 mm. (0,155") | 5,24 mm. (0,206") | 6,56 mm. (0,258") | 7,88 mm. (0,31") |

| 80 mm. (3,15") | 1,4 mm. (0,055") | 2,79 mm. (0,11") | 4,19 mm. (0,165") | 5,59 mm. (0,22") | 7 mm. (0,276") | 8,41 mm. (0,331") |

| 85 mm. (3,346") | 1,48 mm. (0,058") | 2,97 mm. (0,117") | 4,45 mm. (0,175") | 5,94 mm. (0,234") | 7,44 mm. (0,293") | 8,93 mm. (0,352") |

| 90 mm. (3,543") | 1,57 mm. (0,062") | 3,14 mm. (0,124") | 4,72 mm. (0,186") | 6,29 mm. (0,248") | 7,87 mm. (0,31") | 9,46 mm. (0,372") |

| 95 mm. (3,74") | 1,66 mm. (0,065") | 3,32 mm. (0,131") | 4,98 mm. (0,196") | 6,64 mm. (0,262") | 8,31 mm. (0,327") | 9,98 mm. (0,393") |

| 100 mm. (3,937") | 1,75 mm. (0,069") | 3,49 mm. (0,137") | 5,24 mm. (0,206") | 6,99 mm. (0,275") | 8,75 mm. (0,344") | 10,51 mm. (0,414") |

| 105 mm. (4,134") | 1,83 mm. (0,072") | 3,67 mm. (0,144") | 5,5 mm. (0,217") | 7,34 mm. (0,289") | 9,19 mm. (0,362") | 11,04 mm. (0,434") |

| 110 mm. (4,331") | 1,92 mm. (0,076") | 3,84 mm. (0,151") | 5,76 mm. (0,227") | 7,69 mm. (0,303") | 9,62 mm. (0,379") | 11,56 mm. (0,455") |

| 115 mm. (4,528") | 2,01 mm. (0,079") | 4,02 mm. (0,158") | 6,03 mm. (0,237") | 8,04 mm. (0,317") | 10,06 mm. (0,396") | 12,09 mm. (0,476") |

| 120 mm. (4,724") | 2,09 mm. (0,083") | 4,19 mm. (0,165") | 6,29 mm. (0,248") | 8,39 mm. (0,33") | 10,5 mm. (0,413") | 12,61 mm. (0,497") |

| 125 mm. (4,921") | 2,18 mm. (0,086") | 4,37 mm. (0,172") | 6,55 mm. (0,258") | 8,74 mm. (0,344") | 10,94 mm. (0,431") | 13,14 mm. (0,517") |

The faces of the insert must be parallel to each other, and a mechanical stop must be machined into it. In addition, at least 1/3 of the insert must remain inside the housing during the ejection process.

CG864857

CG603035 – 180.000N / 18.356 Kg (40.419lb) CG604035 – 320.000N / 36.712 Kg (80.839lb) CG754049 – 320.000N / 36.712 Kg (80.839lb) CG604075 – 480.000N / 48.950 Kg (107.787lb)

Show More >>

最大可调到1毫米/0.039英寸

由使用的斜导柱决定:

GI010075 – 12mm (0.472”) GI010090 – 15mm (0.590”) GI010105 – 18mm (0.708”)

Show More >>

FV

Show More >>

The valve should not be installed below the injection point. In that position the high temperatures and pressure could negatively influence the valve components and decrease their lifetime.

Yes, on our catalogo page we indicate the size of the hole (E dimension) to be made before installing, the valve can then be removed using the appropiate ejector.

10Bars (145 psi).

Show More >>

RCM

VA

Show More >>

The valve should not be installed below the injection point. In that position the high temperatures and pressure could negatively influence the valve components and decrease their lifetime.

Yes, on our catalogo page we indicate the size of the hole (E dimension) to be made before installing, the valve can then be removed using the appropiate ejector.

On the smaller diametres (5 & 6) extra care needs to be taken to remove the part slowly, knocking softly to avoid damage to the internal mechanisms.

On the smaller diametres (5 & 6) extra care needs to be taken to remove the part slowly, knocking softly to avoid damage to the internal mechanisms.

10Bars (145 psi).

Show More >>

VD

The valve should not be installed below the injection point. In that position the high temperatures and pressure could negatively influence the valve components and decrease their lifetime.

Yes, on our catalogo page we indicate the size of the hole (E dimension) to be made before installing, the valve can then be removed using the appropiate ejector.

VH

The valve should not be installed below the injection point. In that position the high temperatures and pressure could negatively influence the valve components and decrease their lifetime.

Yes, on our catalogo page we indicate the size of the hole (E dimension) to be made before installing, the valve can then be removed using the appropiate ejector.

On the smaller diametres (6) extra care needs to be taken to remove the part slowly, knocking softly to avoid damage to the internal mechanisms.

On the smaller diametres (6) extra care needs to be taken to remove the part slowly, knocking softly to avoid damage to the internal mechanisms.